In the first article of this series, I talked about what the first steps to developing an electric airplane would be, following the Peterman Method™. Now, I’d like to talk through the next step, design. While design and engineering are intertwined in my mind, I’m going to break up talking about both. There is a lot that happens, and we all read in a linear way.

I’ll be touching on the highlights of our process as we go through developing our electric plane. Let’s start with concept development. The “fun” part where we get to allow our imagination and creativity to soar to new heights.

Concept Development

Concept development is one of the most open and creative areas of developing a product, in my opinion. We’ve lined up everything already to give us goals for what we are trying to achieve. Our end goal is defined, we know what kind of impacts we are looking to achieve and to avoid. We know that the project is feasible on every level.

Concept development is core to every good product development process, the Peterman Method™ shares this.

Ian Peterman, CEO Tweet

For us, this is where we would bring in industrial designers, probably a couple of engineers, and start generating ideas. We discuss about how to shape this electric plane.

From an engineering and flight perspective, there are specific limitations. If it doesn’t have wings, can’t fly like a plane. This is the same with other needed features. However, there are more plane “types” than we often see today as commercial planes.

Because our project is aimed at an eco-friendly commercially competitive electric airplane, we would be looking at cargo and passenger variations. We need to match existing capabilities or exceed them with our design.

By using our process, we will be looking at not only the eco-friendly side of things but sustainability in terms of the people and costs involved with this design. Putting passengers first and finding ways to do so in a financially responsible way would be elements of this process as well. So let’s begin!

Concepting Process

We then take all that and begin to sift through to see what can actually stick and be within what we’ve determined as feasible.

With concepting, a lot of what is presented and looked at is often around aesthetics, usability, design language, and features. Sometimes technical ideas are brought forward, hence engineering involvement.

However, there can be multiple sessions like this, some with different focus and expertise in the room.

Areas we’d focus on would be things like passenger comfort and usability, crew ease of use, maintenance, cleaning, and sustainability. These all align with our previous goals of creating a competitive product that was eco-friendly and improved the lives of people.

Working on an electric airplane would mean we’d have an aeronautics or aerospace engineering group review ideas at some point to make sure we’re following the right ideas. I find that just talking to designers and engineers in the industry we’re designing for provides limited new ideas.

read on for more concepting process

We combine both industry experts with decades of experience with designers and engineers from other industries who can look at the problem we’re solving with fresh eyes that don’t have the same limitations built into their thinking.

While initial concepting often starts with brainstorming, it quickly moves to sketches and even models to explore ideas in 3D and more tangible methods.

During this, we involve the client as well at various checkpoints to make sure the design is going in a direction that makes sense, or that we can provide a good argument for while the direction should change.

Good communication during this phase allows us to move quickly and create more concepts that match our client’s needs better. It also allows us to guide our clients in a better direction when we find one.

User Experience and User Interface

With developing an electric airplane, the user experience and interface are important components. Different information and data would need to be shown to the pilots because the power system has changed.

While much of the information would remain the same, there would still be a need to create an intuitive interface that pilots can use to understand the new propulsion system.

In the first part of this series, I mentioned things like a modular design being something that we’d look at to make the electric plane as efficient and sustainable as possible. Looking at modularity would also increase the ability to repair and replace only parts of the plane but also make maintenance easier.

This would impact how the crew and support teams interface with the plane and their experiences. User experience is a broad term, and when we apply it through our process, we include every potential user including the people who make, use, or service the plane.

focus on UI & UX

Giving some focus on user experience allows us to create better experiences for not only the end customers, such as our planes passengers, but everyone else. This means looking at materials, how individual components are interacted with, ergonomics, and what moving through the plane looks like.

Knowing what the most common complaints of other existing planes would give a clear roadmap earlier in this process that could guide us in creating a better designed plane.

While there are the physical user experience and interface, there is also the digital side of this electric airplane. Everything that applies in the physical design also applies to the digital design of the product.

Looking at how the user will interact with the software, what information is needed, and ensuring things like safety come first will create a consciously designed experience that benefits everyone involved.

Modeling and Prototypes

Modeling and prototyping should be done during concepting, especially on large or complicated products.

Ian Peterman, CEO Tweet

Once concepts have begun the reviewing and narrowing process, this is where modeling and early prototyping really starts to take off.

Sketching is great initially, and we love sharing concept sketches with our clients, but it only goes so far. These are often not fully functional models, but are prototypes of specific parts or concepts within the overall project.

In the automotive industry, full-scale clay models are built, however with airplanes, full scale models become a bit of a challenge. To counter this, we’d model specific pieces or sections individually rather than the entire body at once, at least at this early stage.

For developing this electric plane, we’d put together at rough prototypes for sections such as the cockpit, a section of the main cabin, and of course different wing designs so that testing could happen with engineering.

Scale models would be made showing the overall design so our client can see the overall design. These would also serve to be scanned into CAD at some point, once an idea was approved for testing.

model types and uses

We can create models out of clay, foam, wood, and of course 3D. With VR and AR technology, we have even more options for presenting designs to clients. The whole goal of this part of the concepting process is to communicate the form in the best way possible to allow our client to experience the design.

It can also be used for early focus groups, reviewing designs, or validating the final ideas. While an initial validation was done in verifying feasibility, the design must be continually validated as solutions are created to ensure the design will hold up as needed.

These models can also be used in early user studies to get input from people outside the development team. However, they are typically mostly internal to the development team.

Material Selection

Material selection is an important part of concepting the cosmetic and aesthetic parts of the airplane. It is also imperative to the safety and function of the plane.

While there are some products where material can be easily swapped out or changed, something like a plane takes more time. Most of the material selection in designing an electric plane at this point would be for interior materials. Weight is a large factor, so selecting lightweight materials that are also durable will be key.

With the goal of creating an eco-friendly electric plane, material sustainability will be another metric to look at. Things like reducing Volatile Organic Compounds (VOCs), having recyclable or biodegradable materials, and easier maintenance would be areas we’d investigate to ensure the best results possible.

Componentry

Being aware of the components you need on a product will help ensure the design will work.

Ian Peterman, CEO Tweet

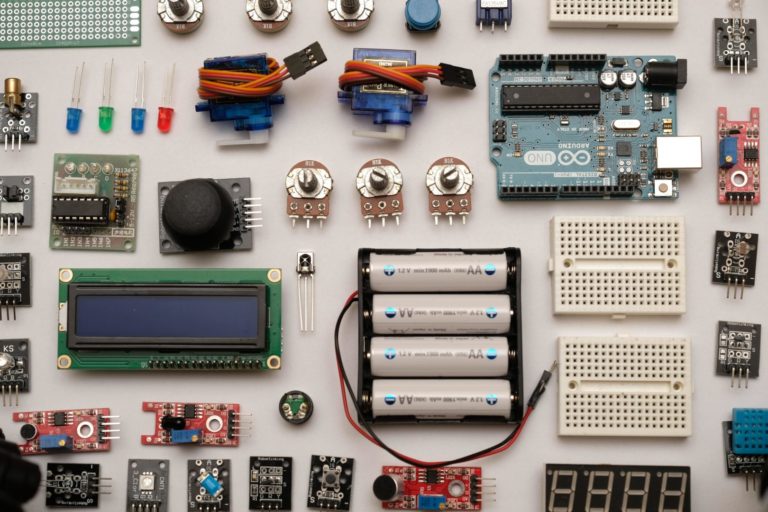

Components are where we start to get into technical requirements and “engineering” work. However, some component selection begins at this conceptual stage because we need to know what kind of scale and limits the components required may create.

Now, if the client wanted to develop everything from scratch, then we would still use existing components as a reference. However, we probably wouldn’t want to completely redesign screws and hardware just because, so we would look at off-shelf components.

Major technologies would at least first reference existing options and so would minor components. Things such as power storage, lighting, fan / propellers, and windows would start referenced by existing components and products.

Then as different components need to be customized, either for intellectual property reasons or for size, weight, or other considerations, then they would be swapped out for custom components.

Design Language

In our example here, this is the first electric plane, meaning there isn’t likely a design history to look at. This means creating a design language from scratch. When we create a design language from scratch, it can be informed by the branding, or even guide what the branding will be of the company.

In launching a new electric plane, the styling will be important as there is some level of expectation that comes with being a newcomer to an industry that you’ll set yourself apart. You also have to, and design language is one of those things.

Now, you might think it isn’t much you can do with a plane. Most people don’t know who manufactured the plane they are on just by looking at it. They typically only know because their flight information may say it, if they even think to look. Unlike cars, the branding hasn’t been primary to airplane manufacturers.

Make a statement

With a new startup like this, we’d want to make that different and make a noticeable impact on the customer. Imagine a new plane that people wanted to be on more than other planes. That plane could be so well designed it drives customers from one airline to another. That is what we can do with good design. Improve the lives of customers so much they only want the product we’ve developed.

By creating a design language, we’ll be setting up for future products and ensuring continuity between products within the brand. This does a couple of things. It creates an experience that people can begin to expect, based on it is your product.

It also can reduce material costs as components and materials will be shared between products. This is important, especially with new products and saving costs where you can in the beginning.

Legal

Every product has legal requirements of some kind. Not being aware is never good for anyone.

Ian Peterman, CEO Tweet

Regulations and other legal requirements are used to check if the design can move forward. These will impact the design. While we don’t limit our initial sessions with legal requirements, we use them in our review process.

With our own internal review process, we eliminate anything that would not meet regulatory requirements. We do this before sharing it with our client. Sometimes there are ideas that are in grey areas or could be approved in certain circumstances. So, we will present those ideas just in case they are possible.

We’ve worked with regulators or experts in those regulations for many products, and this would be no exception. With this kind of regulation, bringing in experts early on, would be important to saving time and costly designs that can’t be approved. We find it beneficial to bring them in even while concepting or before.

Safety

Safety regulations are part of more products than you would ever think of. Even your desk lamp likely went through a review process, or at least its components, before being able to be sold to you. Now, when we work on something like this electric plane, there are many areas of safety to keep in mind.

I mentioned that our concepting process would involve looking at maintenance and cleaning, both of these are done by crews of people. Having a crew work on a product involves additional regulations, such as being aware of OSHA standards in the US.

We would need to design the plane to be safe for more than just the customers, passengers in this case. We’d look at the crew, national and international regulations for flight safety, and ground team, and other support regulations.

In our feasibility study we would have identified all the regulations related to developing this electric plane. This would allow us to guide our concepting and early design work to meet those requirements. This will ensure the electric plane is able to move through the approval process smoothly and avoid potential delays.

Last Thoughts on Design

While technical discussions and engineering are involved in design, I separate design from engineering so that we can focus on other aspects that are generally thought of as part of design.

Most of what we’ve talked about would be done by our industrial design team, however ID and engineering work hand in hand, and there is no line in the sand.

Our designers and engineers work together to ensure that nothing is overlooked. This approach of an integrated team is key to ensuring the success of the project.

Designing a new electric plane is a large undertaking, but one that our development method and team can take on. Our method is scalable and helps ensure we don’t skip parts.

Your Next Steps

Developing An Electric Airplane

Let's talk abou tthe first steps of developing an electric airplane

Related Design BLOG Posts

Why Your Store’s Atmosphere Is Crucial For Business Success

The atmosphere of a store plays a huge role in the success or failure of a business. Hence, it is known as inspirational design, which

Why Product Demos Must Go Beyond Impressions

Gaining profits from product demos is a challenging endeavor for all kinds of companies. On the one hand, you have to demonstrate your products in a way that showcases their functionality and robustness, while on the other hand, you have to present them in a way that gets them sold.

Why Does Your Product Need a Brand?

For all the same reasons your company needs a brand, your product needs one too.